Small and Large Volume CD and DVD Duplication

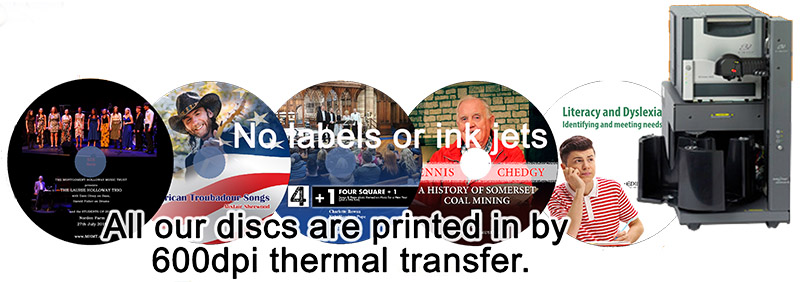

All our discs are now 600 dpi Thermal printed and basic mastering is included.

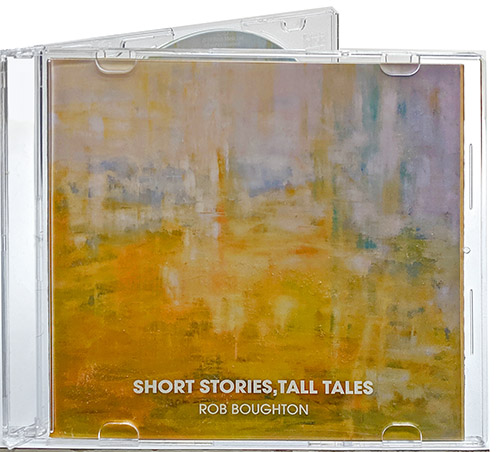

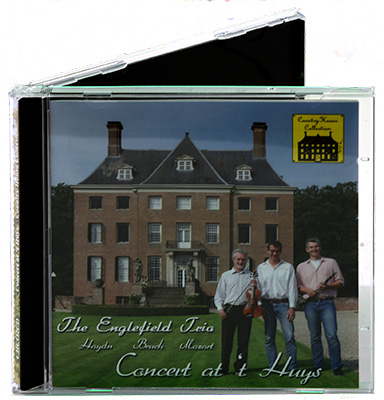

CD in Jewel Case

Templates for

CD in Jewel Case

CD-DVD-Disc PDF

CD-DVD-Disc Photoshop PSD

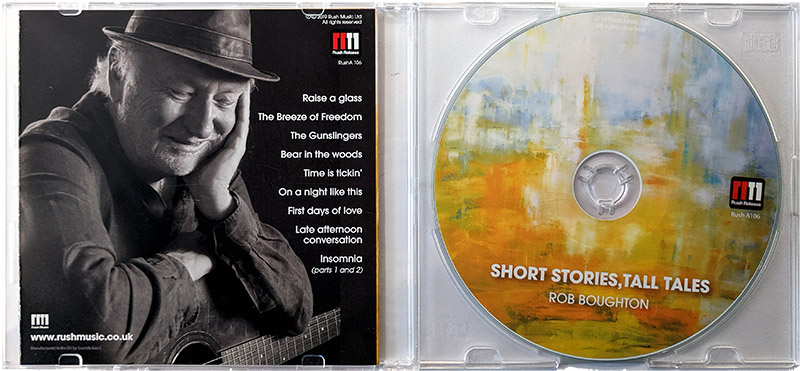

Standard Backliner

Standard 4 page Booklet Spread

The CD Slim Case

The CD Slim case is the most cost-effective packaging for gigging bands. Look good but is inexpensive, and you can carry twice as many in the same space. Great for street and touring musicians.

Including 4 page booklet, thermal printed CD and protective wrap.

50 £2.74 each

100 £1.94 each

250 £1.74 each

WANT TO TALK ABOUT YOUR PROJECT?

We are more than happy to talk through all aspects of your project from the technical issues of recording and mastering through to the look and feel of the packaging. We work closely with Sarah Love our graphic designer and creative director who can bring her skills to bear on the packaging turning your ideas into realty.

CALL NOW ON 01704 264 720

Basic Mastering, (Levelling, Balancing between tracks, CD Text and ISRC codes) is included free of charge.

Mastering, or audio post-production, is the process of preparing and transferring recorded audio from a source containing the final mix into a format that ensures that sound played out through the customers hifi is as you intended in the studio. Tracks may be combined and leveled to improve the continuity of the production. CD Text can display artist details on CD players and ISRC codes added to ensure your recording attracts appropriate royalties when played on radio and TV.

ISRC Codes are obtainable from PPL

| International Standard Recording Codes (ISRCs) are an internationally recognised system to identify recorded music tracks and music videos. |

Duplicated Discs

For smaller runs up to 500 or larger if quick turnaround is an issue we take high quality CDr and DVDrs and burn the tracks on to them individually. The CDr are silver so it is almost identical to a pressed CD. Playable on all but the very oldest CD players. The disk is then printed with an ink jet process which uses Ultraviolet drying inks that won’t wipe off. Or we can use our ‘Precision Laminate’ system where the image is printed onto an acrylic substrate before bonding to the surface of the disk.

All discs are error checked as they are copied followed by a visual inspection prior to packing.

Our Laser printed paper parts then packed into cases and over-wrapped to keep them fresh.

Pressed or Replicated Discs

Glass Mastering is the first stage in the disc replication process. The Master disc content is transferred onto a glass substrate known as the ‘Glass Master’ in order to manufacture discs by injection moulding. CD Stampers are used for the injection moulding of process.

Printing – Once pressed the discs are printed either by a screen printing process where Pantone colour matches are required or for picture discs a white background is screen printed on to the disk before conventional CMYK litho printing.

Raw CD with Colour Label

1000 £0.34p

CD In Jewel Case with Booklet

1000 £0.59p

DVDr in case with wrap

1000 £0.74p

Technicolor is the world’s largest manufacturer of Blu-ray and DVD products, offering end-to-end supply chain management services to Hollywood studios, independent content owners, game and software publishers.

Our services include content preparation, disc replication, finished goods distribution and transportation connecting directly into the Technicolor production control we can upload directly into the glass mastering suit and then track production through the factory and out to the client.